The Mimaki JFX500-2131 can print on an extensive range of materials, such as:

Attention should be paid to ink adhesion, even though it will print onto almost any substrate, levels of adhesion do differ between materials.

The range of possible applications is practically limitless. A selection:

| JFX500-2131 | ||

|---|---|---|

| Head | On-demand Piezo head (6 printheads with 3 staggered configuration) | |

| Print resolution | 300dpi, 600dpi, 900dpi, 1,200dpi | |

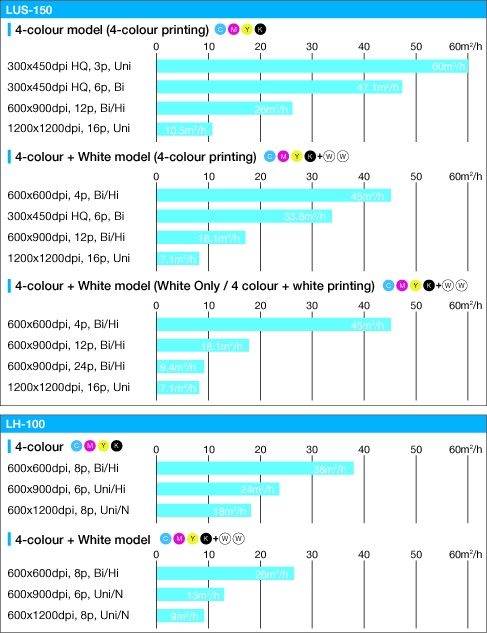

| Ink | Type | UV curable ink : LUS-150 (C, M, Y, K, W) |

| UV curable ink : LH-100 (C, M, Y, K, W, Cl) | ||

| Supply system | Supplied by 2L Ink Station | |

| Ink circulation (*1) | White ink circulation by MCT (Mimaki Circulation Technology) | |

| Ink degassing module | Equipped with MDM (Mimaki Degassing Module) | |

| Inkjet primer | Automatically applied by PR-100 | |

| Maximum print size (W X D) | 2,100 X 3,100 mm (82.7 X 122.0") | |

| Media | Size (W X D) | 2,100 X 3,100 mm (82.7 X 122.0") |

| Height | Max. 50 mm (2.0") | |

| Weight | Less than 50 kg (110.2 lbs.) / m2 | |

| Media table | Air suction by vacuum | |

| Vacuum area | Vertically divided into 4 zones | |

| Print accuracy | Absolute accuracy | ± 0.3 mm (0.01") or ± 0.3% from specified print distance |

| Repeatability | ± 0.2 mm (0.01") or ± 0.1% from specified print distance | |

| UV unit | Equipped with UV LED (Light Emitting Diodes) | |

| Lifetime (*2) | About 5,000 hours | |

| Interface | USB2.0 | |

| Applicable standard | VCCI class A, CE Marking, CB Report, UL, RoHS Directive | |

| Power specifications | AC 200 – 240 V, 50/60 Hz | |

| Power consumption | Less than 2.4 kVA | |

| Operational environment | Temperature | 15 – 30 °C (59 – 86 °F) |

| Humidity | 35 – 65 %Rh | |

| Temperature accuracy | 18 – 25 °C (64.4 – 77 °F) | |

| Temperature gradient | Less than ± 10 °C/h (18 °F) | |

| Dust | Equivalent to normal office level | |

| Dimensions (W X D X H) (*3) | 4,100 X 4,462 X 1,490 mm (161.4 X 175.7 X 58.7") | |

| Weight (*3) | 1,353 kg (2,982.8 lbs.) | |

*1 MCT works only with white ink.

*2 Reference value. There is no guarantee as to the lifetime.

*3 Ink Station is not included in the dimensions and the weight.

*4 RasterLink6 and the standard vacuum unit are bundled with the JFX500-2131.

You are dealing with UV light sources that may harm your health. Please follow below guidelines strictly:

The Mimaki JFX500-2131 employs UV LED printing technology, which does not generate excessive heat, allowing the machine to print directly on a wide range of substrates, including heat-sensitive materials, without any media deformation.

Aqueous or solvent inks require post printing drying. This is eliminated using UV technology and consequently, the media is ready for laminating immediately after printing. The job turnaround time from printing to processing is shortened and improves work efficiency and productivity.

Equipped with the new developed print head (6 print heads with 3 staggered configuration), the JFX500-2131 achieves production speeds of up to 60sqm/h.

Intelligent Microstepping System (IMS)

The JFX500-2131 includes two units of Mimaki’s unique and highly-accurate linear scales controlled by an Intelligent Microstepping System (IMS) for fine step accuracy and dot placement. This results in less banding and the ability to print down to 2-point text with stunning clarity.

High Resolution up to 1200dpi and Variable Drops

High image quality is achieved by utilising a resolution up to 1200 x 1200 dpi and variable dot sizes. The minimum drop size is an fine 7 pico-liters that produces a smooth, natural gradation without granular appearance even in 4-colour mode.

Two types of ink are offered with the JFX500-2131.

Simultaneous white ink under and overprint

Print outstandingly colourful, bright images on transparent and coloured substrates with white ink under or overprint without slowing down the print speed.

A. 4/6 colours only

Without white ink as a basis for overprinting, the colours are not as vivid as they should be.

B. 4/6 colours + white

With the white ink overlay print, the images are bright and vivid.

Mimaki Advanced Pass Systems (MAPS)

Mimaki Advanced Pass Systems (MAPS)The Mimaki Advanced Pass System (MAPS) effectively reduces bandings with multiple printing passes, using a gradational mask pattern. When this option is selected, UV curing is performed more gradually which diminishes any appearance of banding.

![]()